Understanding the Basics: What Does Engine Repair Really Mean?

Overview

Grasp the fundamentals of engine repair with our comprehensive guide. Explore the process, significance, and key engine components.

In the world of heavy-duty vehicles and diesel engines, understanding the mechanics of your truck is essential. It's the key to ensuring the longevity and reliability of your vehicle, whether you're a truck driver, truck owner, or fleet manager. One of the most critical aspects of this understanding is knowing what engine repair entails.

What is Engine Repair?

At its core, engine repair is the process of diagnosing and fixing specific issues within an engine to ensure its optimal functioning. It involves a variety of tasks, from minor adjustments and part replacements to more complex procedures. The ultimate goal is to restore the engine to a state where it can perform efficiently and reliably.

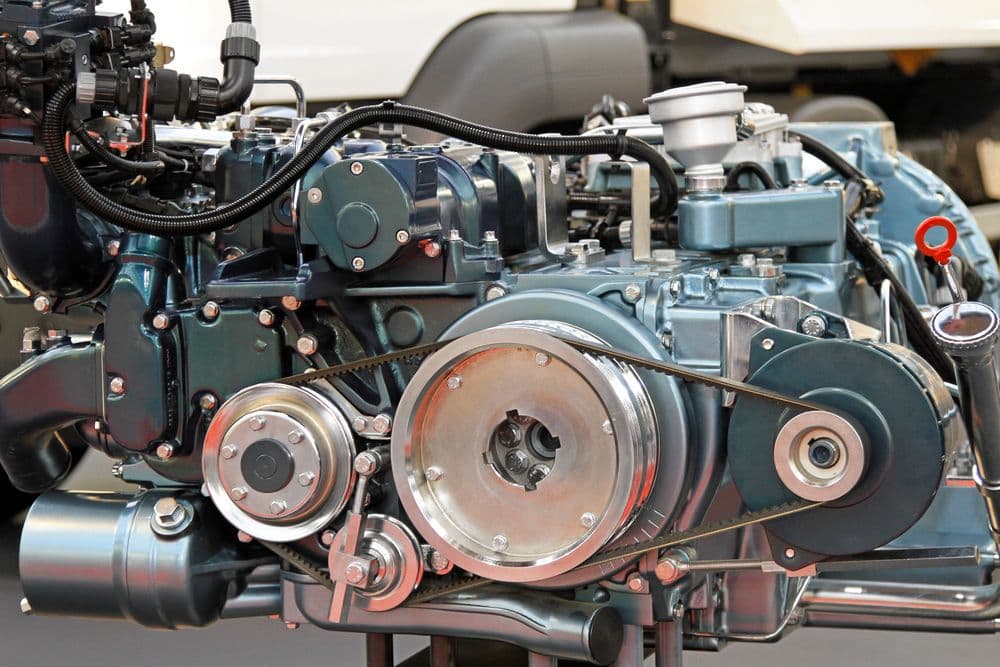

Components of an Engine

To fully grasp the concept of engine repair, it's crucial to understand the main components of a diesel engine and their roles:

- Engine Block: The engine block, or cylinder block, is the main structure of the engine, housing several crucial components such as the cylinders, coolant passages, and oil passages.

- Pistons: Pistons are cylindrical parts that move up and down within the cylinders, compressing the air-fuel mixture and creating power through combustion.

- Cylinder Head: This component, located at the top of the engine block, contains parts such as the valves, spark plugs, and fuel injectors.

- Crankshaft: The crankshaft converts the up and down motion of the pistons into rotational motion to drive the wheels.

- Camshaft: The camshaft controls the opening and closing of the valves in the cylinder head.

- Connecting Rods: These rods connect the pistons to the crankshaft.

- Timing Belt/Chain: This component synchronizes the rotation of the crankshaft and the camshaft to ensure proper timing of the engine's functions.

- Flywheel: The flywheel maintains the continuity of rotation when no power is being applied, ensuring smooth operation.

- Oil Pan: This is a reservoir located at the bottom of the engine, storing the engine oil when it's not circulating through the system.

Understanding these components is the first step in comprehending engine repair because any issue with the engine can usually be traced back to one or more of these parts.

Engine Repair Process

The process of engine repair often begins with a comprehensive diagnosis. This usually involves using specialized diagnostic tools to read error codes from the engine control unit (ECU), a computerized component that manages the engine's operations. It could also include physical inspections, compression tests, and other diagnostic procedures.

Once the problem has been identified, the repair process can begin. This might involve minor adjustments, replacing faulty parts, or fixing specific components. For example, if the issue lies in the fuel injector, it might be cleaned or replaced. If the timing belt is worn out, a new one would be installed. In some cases, more than one component may need attention.

Types of Engine Repairs

Engine repairs can be categorized into two types: minor and major.

Minor Repairs: These are simpler, less time-consuming repairs that usually don't require the engine to be completely disassembled. They often involve replacing or repairing specific parts that are easily accessible. Examples include replacing spark plugs, timing belts, or oil filters, and repairing or cleaning fuel injectors.

Major Repairs: Major engine repairs are more complex and typically require the engine to be partially or fully disassembled. They involve dealing with internal components of the engine, which often means removing the engine from the vehicle. Examples of major repairs include replacing the crankshaft, repairing pistons, or dealing with severe engine damage.

Why Engine Repairs are Essential

Regular engine maintenance and prompt repairs are essential to ensure the smooth operation of your truck. Here's why:

- Optimal Performance: Regularly serviced and well-repaired engines operate at their best. They deliver optimal fuel efficiency, power, and performance, which are essential for heavy-duty applications in particular.

- Longevity: Timely repairs can significantly enhance an engine's lifespan. By fixing minor issues before they escalate, you can prevent severe damage and prolong the life of your truck's engine.

- Safety: Engine issues can sometimes lead to dangerous situations, like unexpected breakdowns. Regular repairs ensure the engine is in safe working condition.

- Cost-Efficiency: While engine repairs come at a cost, they can save you money in the long run. By preventing further damage, you avoid the higher costs associated with major engine overhauls or replacements.

- Downtime Reduction: For truck owners and fleet managers, time is money. Regular engine repairs prevent unexpected breakdowns and reduce vehicle downtime, contributing to more efficient operations and higher productivity.

Who Should Perform Engine Repairs?

Given the complexity and importance of engines, it's crucial that any engine repair is carried out by a skilled and qualified professional. Diesel mechanics have the necessary training and expertise to diagnose and fix issues correctly. They also have access to the right tools and equipment required for such tasks.

Doing engine repairs yourself or entrusting them to an unqualified individual may lead to more harm than good. It could result in improper repairs, further damage, voided warranties, and potential safety risks.

When to Seek Engine Repair?

The right time to seek engine repair can vary depending on the situation. Regular maintenance checks can help identify and fix minor issues before they become significant problems. However, certain signs might indicate that your engine requires immediate attention:

- Unusual noises like knocking, hissing, or rattling

- Excessive smoke from the exhaust

- Decreased power or fuel efficiency

- The engine running roughly or inconsistently

- Warning lights on the dashboard

- Unusual smells, like burning oil or coolant

If you notice any of these signs, it's wise to have your engine inspected and repaired as soon as possible.

Conclusion

Understanding the basics of engine repair is the first step towards maintaining your truck's engine effectively. As a truck driver, owner, or fleet manager, gaining this knowledge can help you make informed decisions about your vehicle's maintenance, ensuring it performs optimally, lasts longer, and remains safe on the road.

Whether it's a minor fix or a major repair, it's essential to trust the job to a skilled professional. With their expertise and the right tools, they can diagnose and repair any engine issues accurately and efficiently.

Remember, timely repairs are not just about fixing problems – they're about preventing future ones. By addressing issues promptly, you can save time, money, and potential headaches down the road.

About This Series

This article is part of our comprehensive series titled Engine Repair vs. Engine Rebuilding, where we dive deep into the world of diesel engine maintenance. We aim to guide fleet managers, truck owners, and drivers in making informed decisions about their big-rig truck's engine.

Next Article: Ready to move forward? Check out our next article: Decoding Engine Rebuilding: A Step-by-Step Breakdown

Join us as we explore each aspect of engine repair and rebuilding, aiming to provide you with the knowledge you need to maintain your diesel engine effectively.

Opening Hours

Weekdays: 9.00am-6:00pm

Saturday, Sunday: Closed

© Advanced Diesel Technology LLC, All Rights Reserved 2023

Powered By: Total Care Websites