A Deep Dive into Diesel Engine Electrical Problems

Overview

Discover how to diagnose and fix electrical and sensor issues in diesel engines. Dive into DIY techniques and learn when to seek professional help.

Welcome back to our ongoing series, "Ignite Your Passion for DIY Diesel Engine Repair". We've been journeying together through the complex world of diesel engines, equipping you with the knowledge to maintain and repair these robust machines. In our previous article, "Fuel and Cooling System Mastery for Diesel DIYers", we navigated the essentials of fuel and cooling systems. We illuminated how to identify and solve common problems, empowering you to take control of your engine's health. Your newly gained understanding of fuel systems and cooling mechanisms is a significant step in your diesel DIY journey.

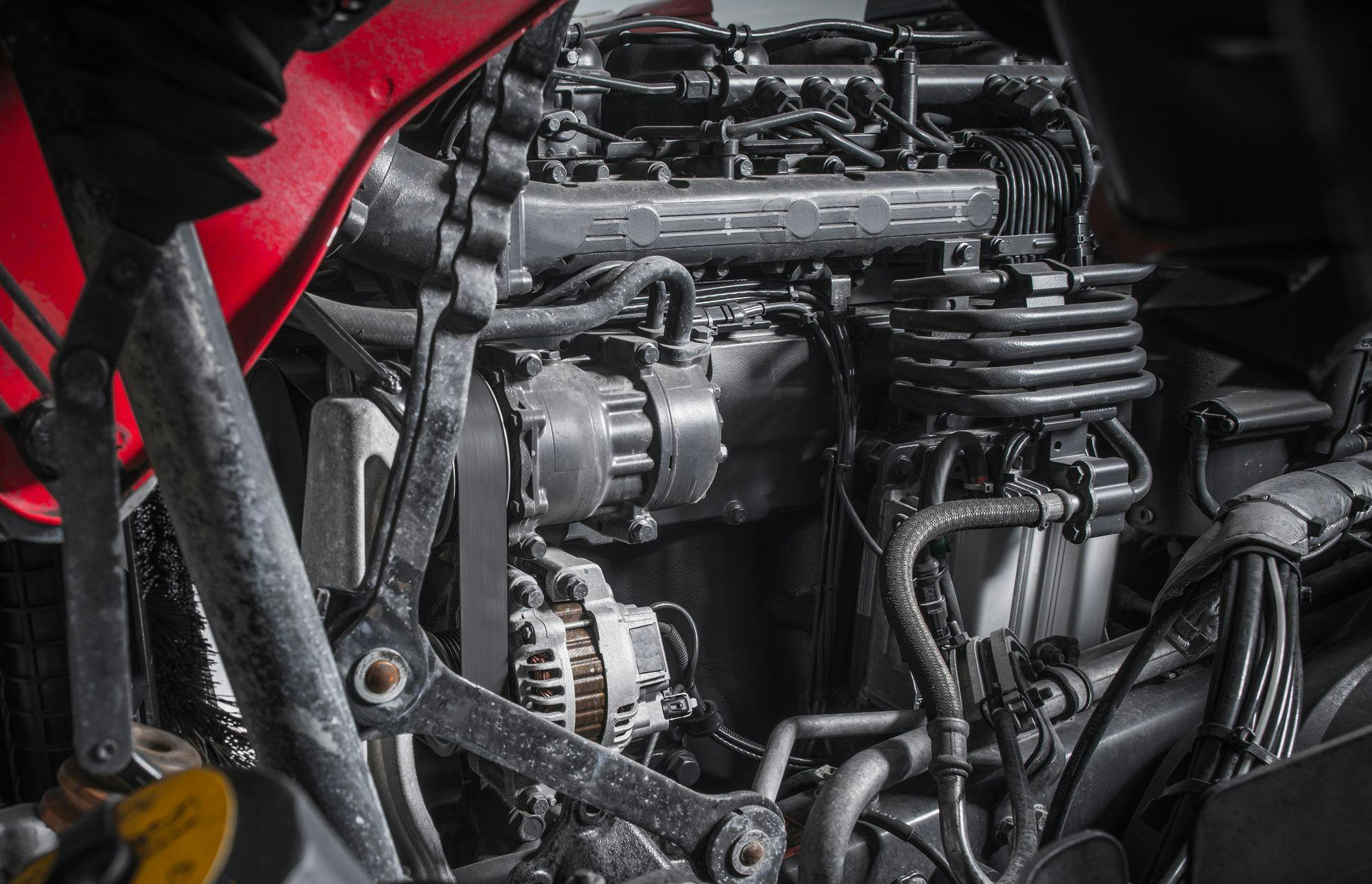

Now, we're about to turn our attention to another vital aspect of your diesel engine - the electrical system and its comprehensive network of sensors. This sophisticated circuitry is the heartbeat of modern diesel engines, ensuring smooth operation, efficiency, and safety. As we move forward, prepare to uncover the mysteries behind these crucial components, enhancing your troubleshooting skills, and fueling your passion for DIY diesel engine care. Let's get started!

Diesel engine electrical systems are fascinatingly complex. They're an intricate network of many components, each playing a pivotal role in the operation of your diesel engine. The battery, the alternator, the starter motor, various sensors, switches, and a multitude of other electrical accessories are all interconnected through a maze-like configuration of wiring, fuses, and relays.

The battery serves as the initial source of electrical power that gets the engine running. The alternator then takes over once the engine starts, generating electrical power for the vehicle's systems and simultaneously recharging the battery. The starter motor is responsible for cranking the engine - it transforms the battery's electrical energy into mechanical energy that sets the engine's components into motion.

Signs of Electrical Problems

Diagnosing electrical problems in a diesel engine can seem like deciphering a complex puzzle. The labyrinthine nature of the electrical system and its interaction with other engine systems make it difficult to pinpoint issues. However, there are certain telltale signs that can indicate electrical problems.

An engine's failure to start could point to a weak or dead battery, a failing starter motor, or a faulty ignition switch. Dim lights could suggest an alternator issue or a poor battery condition, while flickering dashboard lights or erratic behavior of electric controls might point towards a wiring problem or ECU issues. Recognizing these symptoms early on can prevent more serious engine damage.

Understanding the Role of Sensors

Sensors are the unsung heroes of the modern diesel engine. They act as the eyes and ears of the Engine Control Unit (ECU), constantly monitoring various parameters like temperature, pressure, speed, and fluid levels. Sensors feed the ECU with real-time data that it uses to control fuel injection, exhaust emissions, engine timing, and much more. A well-maintained sensor network ensures efficient engine performance, fuel economy, and reduced emissions.

Common Sensor Issues in Diesel Engines

The intricate sensor system in diesel engines is, however, susceptible to issues. One common problem is a faulty oxygen sensor, which can cause your engine to run rich (too much fuel) or lean (too little fuel), leading to poor fuel efficiency and increased emissions. The mass air flow sensor, another key player, directly affects how much fuel is injected into the engine. Its failure can similarly lead to decreased fuel efficiency.

A malfunctioning fuel rail pressure sensor can lead to inconsistent fuel delivery, causing engine performance problems like reduced power and poor acceleration. Recognizing the symptoms of these sensor issues can help you diagnose and address them timely, thus preserving your diesel engine's performance and longevity.

Using Onboard Diagnostics for Troubleshooting

The advent of Onboard Diagnostics (OBD) systems has revolutionized the process of troubleshooting sensor and electrical problems. Modern diesel engines come equipped with an OBD-II system that continually monitors the performance of various engine components. It flags potential problems through trouble codes displayed on the dashboard, which can be read with an OBD scanner.

For instance, a P0131 trouble code indicates a potential problem with the oxygen sensor circuit, signaling the need for further investigation. These self-diagnostic capabilities can be instrumental in preempting serious engine problems, saving you considerable time and repair costs.

DIY Fixes for Sensor and Electrical Issues

While some electrical and sensor issues call for professional intervention, many minor problems can be addressed with a basic understanding of diesel engine operation and a few tools. For instance, a faulty oxygen sensor can often be replaced at home with the right tools and adherence to safety precautions. Likewise, a weak battery can be recharged or replaced without professional help.

However, more complex issues like wiring defects or ECU problems are best left to professionals due to their complicated nature and the potential hazards involved. While addressing these issues yourself can seem daunting, safety should always be your primary concern.

The electrical system and sensors in a diesel engine are vital for its optimal performance. Understanding their functioning and how to diagnose and fix common issues is invaluable knowledge for any diesel engine owner. With tools like OBD systems, even complex troubleshooting becomes more accessible for the average DIY enthusiast.

However, remember that while passion and a willingness to learn can go a long way, complex issues are best left to professionals. The goal should always be a well-functioning, efficient diesel engine- achieved through the right balance of DIY maintenance and professional servicing.

Stay tuned for our next article in this series, where we unravel the mysteries of exhaust, emission control, and performance problems in diesel engines.

Key Terms to Know:

Battery: The power source for starting the engine and powering electrical components in the vehicle.

Alternator: Device that generates electrical power from the running engine and charges the battery.

Starter Motor: An electrical device that converts electrical energy from the battery into mechanical energy to crank the engine.

Engine Control Unit (ECU): A computer in the vehicle that controls a wide range of the engine's functions, such as fuel mixture, ignition timing, and variable valve timing.

Oxygen Sensor: A sensor located in the exhaust system that sends data to the ECU about the oxygen levels in the exhaust, which the ECU uses to adjust the fuel-air mixture.

Mass Air Flow Sensor: A sensor used to find out the mass flow rate of air entering the engine. This information is necessary for the ECU to balance and deliver the correct fuel mass to the engine.

Fuel Rail Pressure Sensor: A sensor that monitors the pressure of the fuel delivered to the engine, ensuring optimal engine performance.

Onboard Diagnostics (OBD): A vehicle's self-diagnostic and reporting capability, used for the detection of faults within the vehicle.

FAQs

What causes flickering dashboard lights in a diesel engine?

Flickering dashboard lights can indicate issues with your vehicle's alternator or wiring, or a problem with the ECU.

What role do sensors play in a diesel engine?

Sensors act as the eyes and ears of the Engine Control Unit (ECU), providing vital data about various engine parameters. This data helps the ECU control different engine functions, including fuel injection, exhaust emissions, and engine timing.

Can I fix sensor issues on my own?

While some sensor issues can be addressed at home, others require professional intervention. A basic understanding of diesel engine operation and the right tools can help fix minor issues, but complex problems are better handled by professionals to avoid potential hazards.

What is an OBD system and how does it help in troubleshooting?

The Onboard Diagnostics (OBD) system is a self-diagnostic tool that monitors the performance of various engine components. It identifies potential problems through trouble codes displayed on the dashboard, which can be read with an OBD scanner. This helps in preempting serious engine problems and can save on repair costs.

Opening Hours

Weekdays: 9.00am-6:00pm

Saturday, Sunday: Closed

© Advanced Diesel Technology LLC, All Rights Reserved 2023

Powered By: Total Care Websites